Influencing Factors of Sharps Container Design

Sharps injury prevention through safe healthcare waste disposal containers is a fundamental part of our brand DNA. Daniels Health was founded to reduce needlestick injuries by providing the very best sharps containers available. We set out in 1986 to develop the world’s safest sharps container (or sharps bin as it is commonly termed), and in 1999 we achieved it after many years of R&D with the launch of Daniels Sharpsmart, a reusable sharps container which to this day is unrivalled for its safety features and proven reductions in needlestick injuries.

Influencing factors that have driven safer sharps containers

Prior to the 1980’s there was very little conscious thought given to sharps injuries and/or safety factors that should influence container design. Few needlestick injuries were reported, commercial sharps containers were rare, and recapping needles was a common practice. It wasn’t until a pre-AIDS seminal study published in 1981 by McCormack and Maki1, that pushed the issue of sharps injuries into a critical healthcare spotlight. Reviewing the causes of 316 reported needlestick injuries and revealing that 8.2% of healthcare workers reported sharps injuries annually, the study authors made the clear determination that two safety factors needed renewed focus – firstly education against the practice of recapping used needles, and secondly the adaption of safer needle disposal systems.

Two years after the study was published, the first healthcare worker occupationally contracted HIV, and suddenly their findings garnered international attention. McCormack’s 1991 follow up study revealed an alarming 18.7% of healthcare workers reported sharps injuries annually, indicating that more than a million healthcare practitioners were suffering needlestick injuries each year. A very clear recommendation came to light that engineered controls (safety devices) were integral to interrupting a dangerous trend.

Container Associated Sharps Injuries

Commercial sharps bins emerged in the 1980’s and introduced an alternative solution to the common practice of needle recapping. With this, came a new subset of sharps injuries, now known as ‘container associated sharps injuries’ (CASI). Until 2001, CASI commonly accounted for between 10-20% of total sharps injuries with sharps containers that lacked basic safety features that would actively prevent against disposal injury. Small lid openings, potential to overfill, penetrable plastic, hand-access and unsecured closure were all factors that saw the earlier-design containers assisting rather than preventing needlestick injuries.

The primary causes of container associated sharps injuries included the following:

- Overfilling or insensitive door causes sharps to bounce out

- Sharps protruding from sharps container due to small aperture/lid opening

- Sharps penetrating through thin-walls of disposable sharps containers

- Hand access into the sharps bin in the absence of a restrictive door or secure closure

- Manipulation of the sharps container without deposited needles being secured by a permanent closure

Introducing Human Factors Engineering into sharps container design

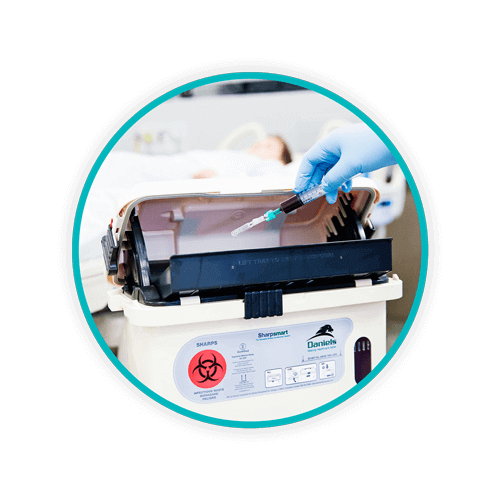

When Daniels introduced its Sharpsmart system, it was a revolutionary approach to sharps disposal. Through human factors engineering, a wide spectrum of human behavior was examined, resulting in a list of safety features that were deemed mandatory to effectively protect the wellbeing of healthcare workers. The Sharpsmart system was and is today the only sharps container solution in the world that provides total protection against the common causes of container associated sharps injuries.

Below are a few of the 13 safety features mandated and finally perfected in Daniels’ 5 year R&D process:

OVERFILL PROTECTION

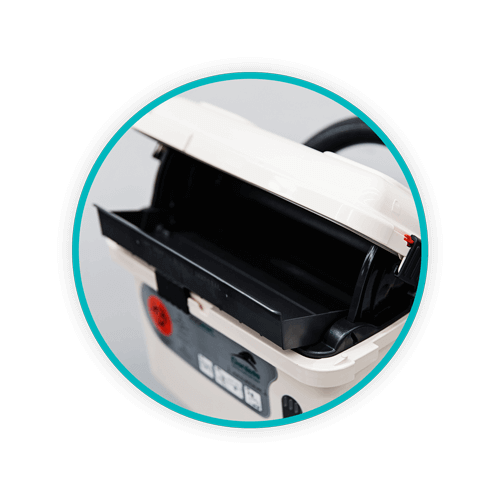

Sharps containers don’t have an endless bottom like Mary Poppin’s travel bag; but sometimes people still try fill them to the very brim. Overfilling is unsafe and against regulations for how full sharps containers can be. The Sharpsmart’s overfill protection tray is automatically engaged when the container reaches capacity, raising the tray and clearly signaling “FULL.”

IMPENETRABLE PLASTIC

IMPENETRABLE PLASTIC

You know how motorcycle helmet plastic is so durable it can protect your precious noggin in the event of an accident? Our containers are made of the same material. The Sharpsmart eliminates sharps injuries and risks from punctured plastic.

LARGE APERTURE WITH NO-HAND-ACCESS SAFETY-TRAY MECHANISM

The Sharpsmart is equipped with a larger opening than your standard sharps container – making it easier and safer to dispose of sharps. An added layer of protection with the opening is the no-hand access safety-tray mechanism. It is impossible to reach in and retrieve any contents from the container. The other Sharpsmart opening option is our Access Plus model – Click here to learn about our (2) types of lid openings.

LIGHT-SHARP ACTIVATION

The tilt-tray in the Sharpsmart can perceive even the most lightweight of sharps – automatically dipping back to dispose of the sharp once it hits the tray.

TEMPORARY AND PERMANENT LOCKING SYSTMS FOR MANEUVERING AND TRANSPORT SECUREMENT

Temporary locks on the front of the Sharpsmart allow you to securely close the container while you transport it to another location to use. Once the container is full, the permanent locks on the side can be activated – ensuring full security until the sharps container reaches a Daniels’ treatment plant.

Learn More About Sharpsmart Features & Benefits

Industry focus on sharps containers today

With the uptake of safety engineered devices designed to disarm a sharp before disposal, and the emergence of safer sharps containers designed to combat preventative injury, container-associated sharps injuries have decreased, however not to an acceptable state. Between 4-11% of total sharps injuries that occur within US healthcare facilities are container-related, equating to a conservative 24,000 needlestick injuries a year. OSHA has enforced the requirement that healthcare facilities examine sharps containers (like other safety devices) annually to determine whether safer containment options are available. The criteria provided is simple: sharps containers must be closable, puncture-resistant, labelled appropriately, and leakproof.

Daniels Sharpsmart container’s Peer Review Accreditation

Daniels Sharpsmart container is the only sharps container in the world backed by multiple peer reviewed studies. A 2 year, 28 hospital before-and-after study published in the American Journal of Infection Control2, examined the sharps injury impact of converting from disposable sharps containers to the Daniels Sharpsmart reusable sharps container.

In the 14 hospitals who converted to Daniels Sharpsmart sharps containers:

- After-Procedure Sharps Injuries (SI) fell 30%

- Disposal Related Sharps Injuries fell 57%

- Sharps Container Associated Sharps Injuries fell 81%

In the control group retaining disposable sharps containers:

- No significant reductions occurred in sharps container associated injuries

- Total Sharps Injuries (SI) increased

Sharps Containers must compensate for human error

Evidenced in all studies and hospital trials is the clear imperative that a sharps container must be a fail-safe solution for safe sharps deposition and require minimal thought from the user. In a high paced, care-intensive patient environment, it’s not practical that a healthcare worker has to think through multiple steps to ensure safe disposal of a sharps – it must be intuitive. There cannot be an option to overfill a sharps container, otherwise it will be akin to the common human dilemma of ‘who replaces the toilet roll’…. There’s always a reason of ‘why not’ and ‘someone else will do it.’ In a sharps container this presents a much more dangerous dilemma because even though it’s just ‘one more sharp’, that one more sharp in a container without over-fill protection could cause a life-altering sharps injury.

Daniels Sharpsmart system has prevented over 20,000 needlestick injuries in six countries and is praised by healthcare workers around the world for its superior safety-first design. Watch the Sharpsmart’s safety engineered features in action here or download our Sharpsmart features and benefits guide which will walk through the 29 unique features of the Daniels Sharpsmart system.

References

1Am J Med. 1981 Apr;70(4):928-32. Epidemiology of needle-stick injuries in hospital personnel.

2https://www.ajicjournal.org/article/S0196-6553(10)00796-0/pdf

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.