Our Washsmart

Regulation Certified Processing: Meets strict wash requirements (OSHA)

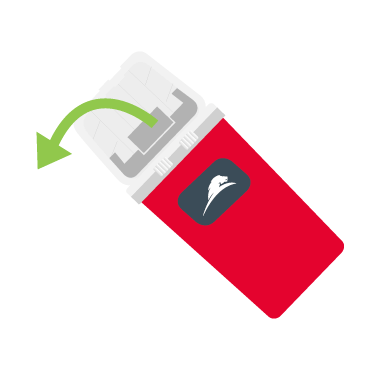

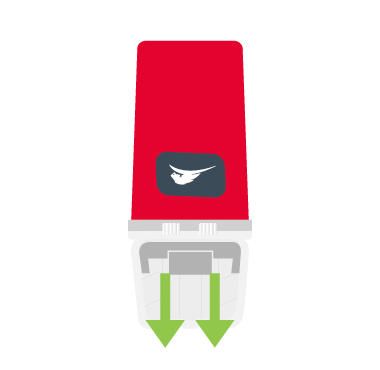

Daniels mechanical Washsmart technology robotically empties and feeds each Daniels Sharpsmart container through a sophisticated 6-stage washing process.

Using a tested combination of water pressure, high temperatures, and biodegradable detergent (no harmful chemicals) to achieve high-level disinfection, the Daniels Washline is ground-breaking in its engineering. Our washing process achieves a 6-log bacterial load reduction, which is a higher sanitization result than any other container washing method.

Daniels Innovation

Our Australian team has driven the innovation of the safest sharps and medical containers in the world for over 40 years. One of our industry-leading inventions is a robotic washing and treatment technology that achieves the highest industry standard in bacterial load reduction. Learn more about our Washsmart and the spirit of innovation behind Daniels global brands.

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.