Hospital Waste Management. A Perspective Inside the Four Walls

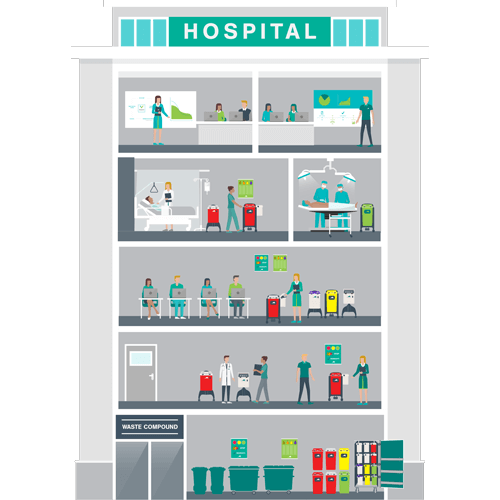

As nursing staff shortages and increased patient intake converge, healthcare systems across the United States along with their frontline clinical and support staff are facing increased pressure to maintain hospital housekeeping while prioritizing patient care. One auxiliary hospital service that is coming under increased strain is medical waste management and, most specifically, its flow throughout a hospital facility. With a lack of time and labor shortages, consistent waste partner service support, and effective waste mapping, there is an increased likelihood that hospitals are seeing a rise in waste build up in soiled utility rooms and dock storage, a decrease in waste segregation efficacy, and pressure on clinical staff with containers overfilling – often posing a risk to both hospital workers and patients alike.

Since the start of Covid 19 the challenges surrounding medical waste management in hospitals and patient care clinics alike have been put under compounded pressure with the shortage of healthcare workers, supply chain strain, and the disproportionate increase in medical waste volumes due to uncertainty of appropriate waste segregation protocols for COVID patient waste.

Medical waste disposal is complex, and, with their primary focus being patient care, healthcare facility staff need independent support when it comes to getting it right. So, what’s the better way? It starts with a partnership approach that takes waste management services inside the four walls of your facility.

TOPICS WE WILL COVER:

1 / Why a four walls approach matters

2 / The four walls approach in practice

3 / A four walls partnership begins before waste is even collected

4 / The benefits of working together

Why a Four Walls Approach Matters

In many healthcare facilities, a medical waste management partner doesn’t have a direct influence on waste management protocols within patient-care areas. Additionally, in many hospitals, it is EVS teams that manage the waste flow and waste storage, not the waste management partner. In such circumstances, the waste partner’s main touchpoint with the hospital’s waste is bin exchange and waste pickup at the facility’s loading dock. Without a single responsible owner of the waste output throughout its entire journey from point of generation through to storage, and finally to transport and treatment, the following inefficiencies can arise:

- Waste handling protocols can become siloed at a ward or department level, leading to inconsistencies across an entire hospital location or system

- Without an independent waste expert mapping waste flow and assigning correct locations for bin placement, bins are often positioned in locations that are most accessible for service access, and not ideally positioned for safety and point-of-use disposal

- Lack of waste bin audits and understanding of waste generation per location, makes it impossible to understand problem areas, and focus training and education support resources to department-level segregation improvements

- There are no audits of waste volumes at a location level to identify where containers need to be rightsized, with larger (or smaller) containers installed to adequately cater for a ward or a department’s generated waste volumes.

- With multiple people involved in waste collection and movement, waste can sometimes be touched up to 7 or 8 times before it reaches the loading dock, impacting not only labor efficiencies but also driving increased cross-contamination risks.

- Lack of consolidated reporting across all touchpoints to drive waste segregation improvements, waste reduction, and cost reductions

Getting waste disposal right within a hospital system can be a major burden on both clinical and EVS staff. Not only does it take focused time and energy, but the byproduct of getting it wrong has a significant cost impact – compliance infringements for non-compliant disposal, and significantly increased costs from improper segregation. Improper segregation can go two ways:

- Firstly, if waste is under-categorized (i.e., RCRA hazardous waste disposed in an red bag), this poses a risk not only to staff handling the waste, but also to downstream service staff during transport or treatment. Additionally, the properties of that waste can have combustible or ignitable effects when commingled that put support staff at increased risk when handling. Due to the heightened risk of such waste streams, improper segregation has a heavy compliance price tag.

- Secondly, if waste is over-categorized (i.e., if red bag waste is disposed in a black RCRA hazardous waste container), the costs of waste collection and disposal are compounded. The pounds generated across all healthcare waste streams are priced according to the risk profile. For a lesser risk waste like RMW to be disposed as a higher risk waste, hospitals can be paying up to 80% more per pound for collection and treatment.

Due to these complexities, medical waste management requires a different, consultative approach, one that relies on a solid understanding of your facility’s specific needs to develop a “just-right” program to avoid the pitfalls of improper segregation.

The Four Walls Approach in Practice

The benefits of a consultative, “inside the four walls” approach are clear, but what does it look like in practice?

At Daniels Health, our four walls approach begins from the moment someone reaches out from a healthcare facility, before we even have a contract in place. From our first initial conversation with a hospital system, our goal is to identify current areas of need and the hospital’s goals (safety, sustainability or efficiency objectives) so that we can determine the most appropriate, cost-effective services. This “evaluation” will most often include the following:

- Site assessment, evaluating a cross-section of hospital departments including surgery, patient-care wards and ICU to understand current waste practices across the hospital

- Visual audit of bin locations, waste flow across a facility and loading dock optimization to understand efficiency improvements in labor, movement and space utilization

- Bin audits of higher risk and lower risk waste streams to determine current waste segregation efficacy

Our four walls approach is not a “one size fits all” program, it is very much a bespoke service solution designed around a healthcare organization’s challenges and goals. Once a partnership is in place, we support with the development of Key Performance Indicators (KPIs) that are designed to help reduce overall waste volumes and minimize the cost and risks associated with your medical waste program. Learn more about the importance of healthcare waste management.

These goals are not determined in a vacuum, but are formed by working directly with clinical, EVS and purchasing stakeholders within your facility.

A Four Walls Partnership begins before waste is even collected

PRE-INSTALLATION

Before we onboard any hospital, all aspects of the waste journey, from bin and container placements, safety and use at primary points of care, container sizes (to meet varying volume requirements by location and department) and waste collection and movement, are mapped to achieve maximum efficiency and minimum patient interruptions. Additionally, care is taken to ensure that we are providing optimum education materials that address the current gaps in waste knowledge, as well as on site and ongoing digital training that will ensure best practice is maintained throughout the waste service partnership.

INSTALLATION AND ONBOARDING

During the onboarding process, our installers follow the blueprint of container placement, safe mounting heights, and right-fit bins at each location level that will optimize best-practice waste segregation. Onsite training is provided, along with QR codes fitted onto each container to aid healthcare workers in the safe use of their new sharps or medical waste containers. During the installation process, we assess any areas that are generating greater volumes of waste than predicted and determine whether larger containers are required or additional training is necessary to support staff in waste segregation methodologies.

POST INSTALLATION

After installation, we continue to support with ongoing training and process improvements, generating waste and container exchange reports that immediately identify any areas of the hospital’s waste generation that are falling outside of expected parameters. Perhaps a situation arises with confusion around hazardous, pharmaceutical, or just regular medical waste. In the past, your staff may wonder if they were making the right calls, but with Daniels’ unique inside the four walls approach, any custom training and resource guides are designed specific to each facility and can be easily referenced at the point of disposal.

Once things are fully up and running, our clients can expect consistent service. One of our own critical KPIs is “Delivery in Full, On Time” (DIFOT), which measures the number of services that are completed as expected from the client. We boast a DIFOT score of 98.75% which is higher than many of the largest logistics companies in the US.

There are many factors to achieving this level of consistency; it’s safe to say that it is not a single person or department owned achievement. At Daniels, our entire company from our support office through to our field and operational staff are 100% focused on ensuring minimum disruption to patient care. For our drivers and operational staff this means effective routing with daily analysis of any non-conforming projections and proactive communication of any route abnormalities; for our customer service staff it means immediate response to our customers if a planned service is going to be disrupted along with iron-tight case management with inbuilt escalation to ensure that every issue is tracked and documented, and for our support teams it means building systems and processes that will support service efficiency – from reporting, to manifesting, to direct customer communications. Learn how hospitals dipose of healthcare waste.

When we onboard a hospital, or even before we sign a contract, it is not just our sales managers on site – it is our field service managers, our state operations leaders, and our regional leaders on site – at Daniels, we firmly believe that customer success is owned by every individual and leader in our business. To support partnership excellence, executive business reviews are performed regularly, with service data and analytics reviewed: these meetings between our account management staff and a hospital’s key stakeholders are the forum for critical conversations around service performance, and alignment in troubleshooting any aspects of the waste volumes, container exchanges or cost outputs that are not meeting expectations on either side of the partnership.

The Benefits of Working Together

At Daniels we are dedicated to making life easier for all staff handling waste within hospital facilities. We challenge and change the way hospitals view their medical waste streams by approaching waste disposal holistically and taking into account the full cost of ownership.

One of the things we pride ourselves most on, beyond our industry-leading service, is our people. We have an amazing group of dedicated individuals who not only put the needs of our customers ahead of their own but are, genuinely, nice people! Terry Duffina, director of Sustainability, at Stanford University Health offers this “Oh [Daniels] is wonderful. Everybody has been very polite, very respectful. Very kind. Very timely with responses. Just very nice, very nice people in general.”

We understand that unique needs arise for every hospital and, even more narrowly, every ward and department; our approach of working “inside the four walls” not only provides a unique holistic view of waste flow and output from a clinical perspective, but also helps us to partner with our customers in driving perpetual improvements in waste reduction, sustainability goals, compliance and cost optimization. The principles of this approach have sustained what has now become industry known as “The Daniels Difference” – a waste management partnership that achieves excellence across all service parameters to achieve the one thing we all exist to support – safety and excellence in patient care.

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.