Case Study: 50 Tonnes of Plastic Reduced Annually with a Reusable Sharps Container

Carbon Footprint can be significantly impacted by transport distances between polymer manufacturer, container manufacturer, user and processing facilities. However, more significant than this is the manufacturing, treatment and landfill burden of single use plastic containers in healthcare settings. The carbon footprint and GHG Emissions of Loma Linda University Health were exceeding sustainability goals and a key area of focused adjustment was the environmental impact of their purchasing and supply chain.

So when single-use sharps containers are contributing heavily to Greenhouse Gas Emissions, how is that problem solved?

In this blog:

- The Challenge: Insupportable volumes of plastic

- Our Approach: Conduct a Life Cycle Assessment of Impact

- The Solution: Replace disposable sharps containers with reusable containers

- The Results: 50 Tonnes of plastic reduced annually

Unlike GHG reduction strategies dependent on changes in staff behavior (waste segregation, recycling, turning off lights, car-pooling, etc), purchasing strategies can enable immediate, sustainable and institution wide GHG reductions to be achieved. Large transport distances between polymer manufacturer, container manufacturer, user and processing facilities, can significantly impact the carbon footprint of sharps containment systems.”

McPherson B, Sharip M, Grimmond T. 2019.

Loma Linda University Health, an 1100-bed US, 5-hospital system were struggling with the levels of Greenhouse Gas (GHG) Emissions produced throughout their health system.

As a large system, there were multiple factors contributing to the facility’s environmental impact including manufacturing and supply chain, transport and operations. Loma Linda recognized that their exclusive use of disposable sharps containers across the health system was negatively contributing to their GHG emissions.

We used a “cradle to grave” life cycle GHG tool to examine the GHG emissions during 12 months of facility-wide use of Disposable Sharps containers and Daniels Reusable Sharps containers at Loma Linda University Health.

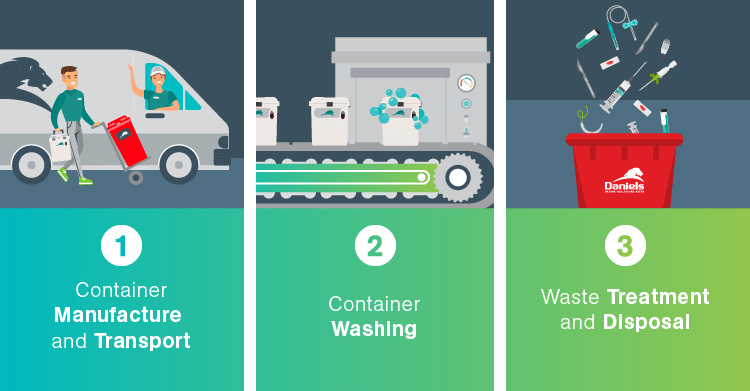

Primary energy input data was used to calculate the GHG emissions (C02, CH4, N20) expressed in metric tonnes of carbon dioxide equivalents for each container system. The scope included:

- Container Manufacture and Transport

- Container Washing

- Waste Treatment and Disposal

Greenhouse Gas emissions from all processes within these four life cycle stages were summed to estimate each container system’s carbon footprint. Emission totals were workload-normalized and analyzed using CHI2, significance set at p ≤ 0.05 and rate ratios at 95% CL.

Our solution to reducing the environmental impact of Loma Linda’s supply chain was our reusable, hands-free sharps container: The Sharpsmart.

Loma Linda University Health replaced its disposable sharps containers with the Daniels Sharpsmart reusable sharps container. In the year prior to conversion, and the year post conversion, all energy-using processes required by each containment system’s life-cycle were reviewed. Unit process GHG were collated into the following life-cycle stages:

- Manufacture (of polymer and containers)

- Transport

- Washing of the reusable sharps containers

- Treatment & disposal

We assessed GHG emissions from all energy used in these processes (vehicle fuel, gas, electricity, water supply and treatment) and in the manufacture and life cycle of ancillary products (pallets, transport cabinets, cardboard boxes, wash products). The Sharpsmart reusable sharps container is certified for 500 uses; during the study period these containers were reused an average of 12.0 times/year at Loma Linda, giving a theoretical ‘‘end-of-life’’ lifespan of 41.7 years.

Converting to reusable sharps containers, Loma Linda reduced its annual GHG by 162.4 MTC02eq, and annually eliminated 50.2 tonnes of plastic disposable sharps containers and 8.1 tonnes of cardboard from the sharps waste stream. The Greenhouse Gas emission impact was derived from multiple factors including containers manufactured, plastic landfilled and the mitigated requirement for cardboard boxes. In a single year, Results showed:

- Sharps container manufacturing requirements reduced from 48,460 disposable containers to 3,195 reusable containers

- The landfilling of sharps containers was eliminated, this averted 35,925 plastic containers from landfill

- 31.8 tonnes of plastic was averted from landfill

- 18.4 tonnes of plastic was averted from incineration

- 8.1 tonnes of cardboard boxes was eliminated

- Sharps container exchanges were reduced from 48,460 exchanges to 33,356 exchanges

- MTC02eq GWP was reduced from 248.62 to 86.19 metric tons

The impact of repeated disposable sharps container manufacture and one-off reusable sharps container manufacture is best illustrated over multiple years. In the Loma Linda University Health scenario over a 10-year period, 484,600 disposable sharps containers would need be manufactured compared to 2783 reusable sharps containers (plus 4,120 chemo disposable containers), and would divert 502 tonnes of plastic from landfill or incineration.

Brett McPherson1, Mihray Sharip1 and Terry Grimmond2

1 Environmental Health, Loma Linda University Health, San Bernardino, CA, United States of America

2 Grimmond and Associates, Microbiology Consultancy, Hamilton, New Zealand

The published Peer Reviewed study can be found here.

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.