Before and After Sharpsmart: 28 Hospital Case Study

Ascension Health, the largest Catholic and nonprofit health system in the US, was an early adopter of sharps safety devices like “smart syringes” (sharps that have a retractable mechanism or a way of protecting the user once the sharp has been used). They found these devices helped reduce sharps injuries initially, but that their annual decrease in sharps injuries had slowed.

What other measures could be taken to reduce the risk of sharps injuries to healthcare workers? This case study explores the addition of a new sharps injury reduction strategy – testing the impact on 14 hospitals that adopted the strategy compared to 14 hospitals that did not.

In this blog:

- The Challenge: Identifying Additional Sharps Injury Risks

- Our Approach: Implementing a Safety Engineered Sharps Container

- The Solution: Expanding Sharps Injury Categorizations

- The Results: Control Group vs. Study Group

Safety-Engineered Sharps are defined by OSHA “as a non-needle sharp or needle device with a built-in safety feature or mechanisms that effectively reduces the risk of an exposure incident.” Examples of safety-engineered sharps include:

- syringes with guards or sliding sheaths

- retractable needle systems

- shielded or retracting scalpels

Ascension Health had adopted Safety-Engineered Sharps Devices like the above but sought to continue reducing their annual sharps injuries.

To expand their sharps injury reduction strategies, container-associated sharps injuries were identified as a subset to address. This study tested the hypothesis that sharps containers that qualified as Safety-Engineered Devices could reduce sharps injuries.

Sharps containers are associated with sharps injuries, and more than 90% of these injuries are related to container design”

Terry Grimmond

STEP 1

The Safety-Engineered Device, the Sharpsmart sharps container, was adopted by study group hospitals between 2006 and 2007. During this time, no additional Sharps Injury (SI) intervention was introduced to the hospital. In-service training for staff on how to use the Sharpsmart was held on the day of implementation and repeatedly over the following weeks.

Employee descriptions of their sharps injuries were obtained retrospectively from each hospital’s Ascension Health-standardized detailed sharps injury log for 12 months before, and for 12 months after, adoption of the Sharpsmart sharps container system. Staff who suffered sharps injuries were unaware of the study at the time of their injury report.

To eliminate the risk of placing sharps injuries in an incorrect study period, data for the month when the Sharpsmart implementation took place were excluded.

STEP 2

In a before and after intervention study from 2006 to 2008, we examined the impact of conversion to the Sharpsmart sharps container with its enhanced engineering, on sharps injuries categories in 14 Ascension Health hospitals. This study group was also compared with a control group of 14 similarly sized Ascension Health hospitals who did not convert to Sharpsmart – they retained their current disposable sharps container.

Together, the 28 hospitals were selected to examine the impact of conversion from disposable sharps containment systems to the Daniels Sharpsmart reusable container.

STEP 3

Total Sharps Injuries (SI) and Total Container-Associated Sharps Injuries (CASI) figures were obtained for 2006 and 2007 from Ascension Health standardized corporate summaries of sharps injury categories from the 14 control group hospitals.

Full-Time Equivalent Staff (FTE) data, the unit of measure equivalent to an individual’s work, was obtained for all hospitals for each study period and used as the sharps injury denominator.

Sharps injury categories per 1000 FTE Staff were used to compare sharps injury rates before and after. In study group hospitals, average daily census data was obtained for the year before the adoption of the Sharpsmart to enable comparison of sharps injuries per 100 occupied beds with national databases. The study was reviewed and approved by the Ascension Health System Office and ethical boards.

To properly test the hypothesis that that sharps containers with enhanced engineering can reduce sharps injuries – it required the categories of sharps injuries to be expanded from the initial scope. Sharps injuries in study group hospitals were categorized as follows:

- During-procedure,

- After-procedure-but-before-disposal (for example, “smart syringe” activation, reprocessing, transporting sharps to a container, recapping);

- Container-Associated Sharps Injuries (CASI)

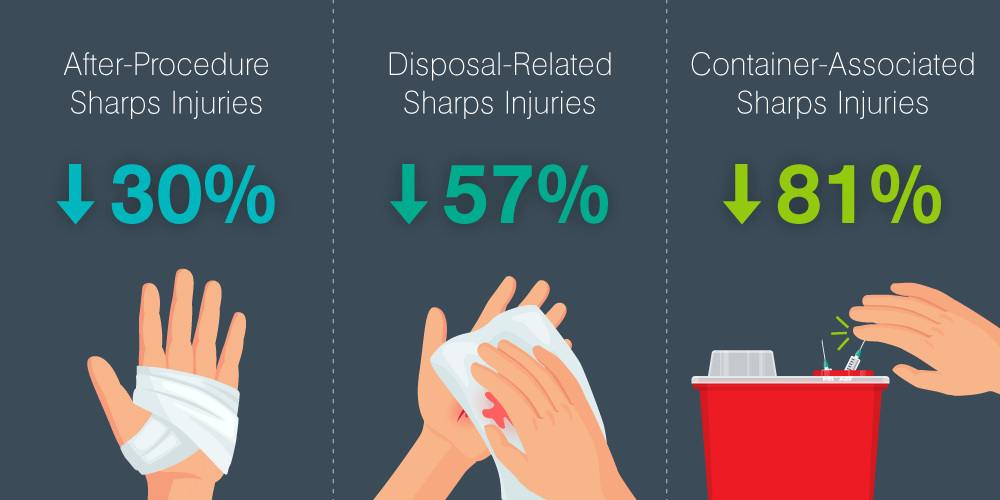

In this study of 28 Ascension Health Hospitals, it was found that…

In the 14 hospitals that converted to Daniels Sharpsmart Reusable Sharps Containers:

- After-Procedure Sharps Injuries fell 30%

- Disposal-Related Sharps Injuries fell 57%

- Container-Associated Sharps Injuries fell 81%

In the control group of 14 hospitals that retained using disposable sharps containers:

- No significant reductions occurred in container associated injuries

- Total Sharps Injuries increased

With these findings, one can ascertain that implementing a safety-engineered sharps container, such as a Sharpsmart, proves to be an effective sharps injury reduction method. The Daniels’ Sharpsmart container is engineered with 20+ inbuilt safety features including a large horizontal aperture, sensitive counterbalanced door, large atrium, and passive overfill prevention.

To review additional data on how Sharpsmart impacts sharps injury reduction efforts, view our full case study library here.

References

1. Grimmond T and Naisoro W. Sharpsmart: Impact of Engineering on Sharps Injuries., American Journal of Infection Control 2010; 38: Pages 799-805.

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.